“Pumping and Hydraulics’ Solutions for Irrigation and Water Supply”

ABN: 92 105 345 506

Corrosion Prevention

Corrosion prevention is one of the most important issues in pumping station design and water engineering, especially so in the northern Australian and Pacific tropical environment.

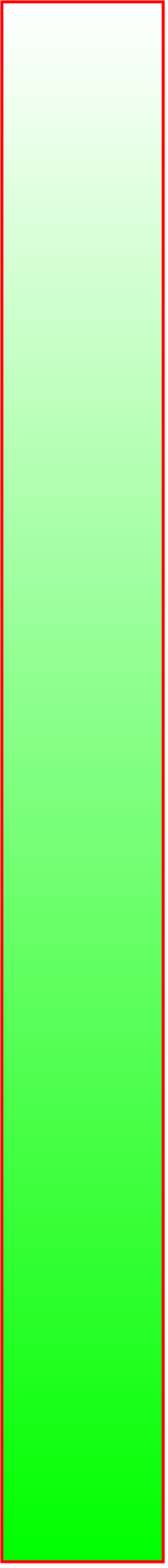

Galvanic Series

In assessing corrosion potential of interacting metals, consideration such as the relative position of different interacting metals on the Galvanic Series is extremely important.

Usually, the higher the metal is on the chart, the more anodic it is and will sacrifice itself (corrode away) for other metals lower on the chart

However, the position of metals on the Galvanic Series (chart right) is not the only consideration for corrosion potential.

Sometimes, it may not be practical to avoid dissimilar metals in close proximity, and so consideration can be given to favourable area ratios of exposed surfaces, electrical insulation or impressed current.

There are many types of corrosion to be considered in pumping and pipeline environments.

Types of Corrosion in Irrigation

These include, (but not limited to)

In assessing corrosion potential of interacting metals, consideration such as the relative position of different interacting metals on the Galvanic Series is extremely important.

Usually, the higher the metal is on the chart, the more anodic it is and will sacrifice itself (corrode away) for other metals lower on the chart

However, the position of metals on the Galvanic Series (chart right) is not the only consideration for corrosion potential.

Sometimes, it may not be practical to avoid dissimilar metals in close proximity, and so consideration can be given to favourable area ratios of exposed surfaces, electrical insulation or impressed current.

There are many types of corrosion to be considered in pumping and pipeline environments.

Types of Corrosion in Irrigation

These include, (but not limited to)

Source: http://www.hghouston.com/coppers/brass78.htm

In his Associate Diploma Mechanical Engineering studies at SAIT, Rob majored in Corrosion Prevention with a project to evaluate the effectiveness of radiator corrosion inhibitors. See photo right. (by the way, Alfloc was the best performer!)

Through Rob’s studies in Metallurgy, Engineering Materials, Strength of Materials and Corrosion Prevention at the South Australian Institute of Technology, plus a lifetime career with corrosion experiences both good and bad, Tallemenco is able to provide clients with the best corrosion prevention advice and applications for pumping station design and general engineering.

Through Rob’s studies in Metallurgy, Engineering Materials, Strength of Materials and Corrosion Prevention at the South Australian Institute of Technology, plus a lifetime career with corrosion experiences both good and bad, Tallemenco is able to provide clients with the best corrosion prevention advice and applications for pumping station design and general engineering.

Evaluating corrosion inhibitors. Photo, R Welke

Uniform Attack-most common type, proceeds uniformly over entire exposed surface, such as ungalvanised steel sheet.

Galvanic Corrosion-sometimes refered to as bi-metallic corrosion, Eg, aluminium and stainless steel. The lesser noble metal (aluminium) will corrode away at the expense of the more noble metal (stainless steel)

Concentration Cell Corrosion, also known as "Differential Oxidation" or "Crevice Corrosion". Commonly occurs around anchor bolts, bolt heads and joining plates, or anywhere where water can collect, but not immerse. Especially catastrophic when powder coatings fail.

Pitting Corrosion-often caused by surface impurities which act as bi-metallic corrosion, propogation enhanced by differential oxidation. Catastophic in short time, especially when iron filings contaminate the surface of stainless steel from workshop activities.

Erosion Corrosion. Common in areas of high water velocity, such as pump casings, or downstream of throttled valves. Jetting fluid erodes surface protection (eg oxides on SS or galv. on steel) forms unprotected areas, resulting in pitting and or bi-metallic corrosion.

Cavitation Corrosion-caused by formation and collapse of vapour bubbles near metal surface. Classic failure mechanism of pump impeller due to running pump off the end of its curve or in poor NPSH conditions.

Parting Corrosion-sometimes called dezincification, results from zinc being dissolved from solution in brass (70Cu-30Zn), leaving honeycombed 90% copper residue. Addition of trace of arsenic prevents zinc from dissolving, hence Dezincification Resistant (DR) brass. Parting corrosion also occurs in cast iron, where iron disolves from iron-carbon matrix, leaving pump casings brittle and weak (also known as graphitisation) Seen in ageing pump casings.

Galvanic Corrosion-sometimes refered to as bi-metallic corrosion, Eg, aluminium and stainless steel. The lesser noble metal (aluminium) will corrode away at the expense of the more noble metal (stainless steel)

Concentration Cell Corrosion, also known as "Differential Oxidation" or "Crevice Corrosion". Commonly occurs around anchor bolts, bolt heads and joining plates, or anywhere where water can collect, but not immerse. Especially catastrophic when powder coatings fail.

Pitting Corrosion-often caused by surface impurities which act as bi-metallic corrosion, propogation enhanced by differential oxidation. Catastophic in short time, especially when iron filings contaminate the surface of stainless steel from workshop activities.

Erosion Corrosion. Common in areas of high water velocity, such as pump casings, or downstream of throttled valves. Jetting fluid erodes surface protection (eg oxides on SS or galv. on steel) forms unprotected areas, resulting in pitting and or bi-metallic corrosion.

Cavitation Corrosion-caused by formation and collapse of vapour bubbles near metal surface. Classic failure mechanism of pump impeller due to running pump off the end of its curve or in poor NPSH conditions.

Parting Corrosion-sometimes called dezincification, results from zinc being dissolved from solution in brass (70Cu-30Zn), leaving honeycombed 90% copper residue. Addition of trace of arsenic prevents zinc from dissolving, hence Dezincification Resistant (DR) brass. Parting corrosion also occurs in cast iron, where iron disolves from iron-carbon matrix, leaving pump casings brittle and weak (also known as graphitisation) Seen in ageing pump casings.

Last Update

Nov 8th 2019

Nov 8th 2019

Tallemenco Pty Ltd, Windsor Gardens, SOUTH AUSTRALIA, 5087.

ABN: 92 105 345 506

Mobile 0414 492 256

Intn'l: Cell +61 414 492 256

Skype: robwelke

ABN: 92 105 345 506

Mobile 0414 492 256

Intn'l: Cell +61 414 492 256

Skype: robwelke